Products

AQUAFLUX™ Series String Wound------ Max Wound Process to add 30% Material

AQUAFLUX™ Series String Wound cartridge filter is made by 100% PP string. Max wound process to add 30% material for great dirty holding capacity. Widely chemical compatibility. Special connecter for different work condition.

Feature:

- Max wound process add 30% weight

- Widely chemical compatibility

- Special connecter for different work condition

Application:

- Sea Water Desalination

- Amine

- Petro Chemical

- Solvent based

- paints & coatings

- Power Plant

| Material Construction: | |

| Filter Media | PP/Cotton/Glass Fiber |

| Core | PP/SS 304/SS 316 |

| Specification: | |

| Length | 10’’~70’’ |

| Micron Rate | 1μm~150μm |

| Diameter -OD | 63mm, 114mm |

| -ID | 28mm |

| Operation Condition: | |

| Max. Pressure Drop | 0.33Mpa |

| Max. Working Temp. | 80℃&120℃ |

| Change-Out Pressure Drop | 0.25Mpa |

| Min Buest Pressure | 0.50Mpa |

| PH Value | 4~11 |

Order Information:

| Application | Type | Material | Length | Micron | Adaptor | Core | Sealing |

| I | SW | P | 10 | F | D1 | P | S |

| F-Food&Beverage

C-Chemical I-Industrial Water Treatment |

SW-General String Wound

SW1-Clean String Wound SW2-XTL String Wound SWB-Big Blue String Wound |

P-Polypropylene

C-Absorbent Cotton G-Glass Fiber |

10-10‘’

20-20‘’ 30-30‘’ 40-40‘’ 50-50‘’ 60-60’’ 70-70’’ |

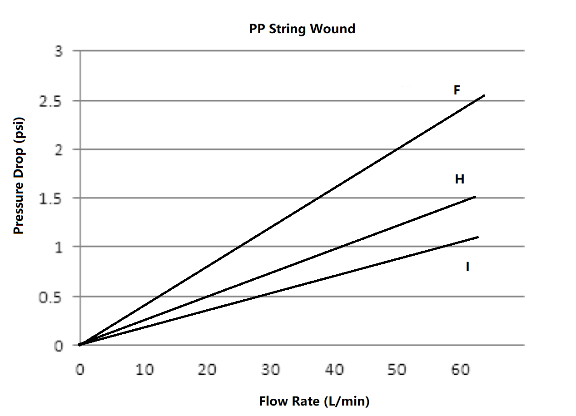

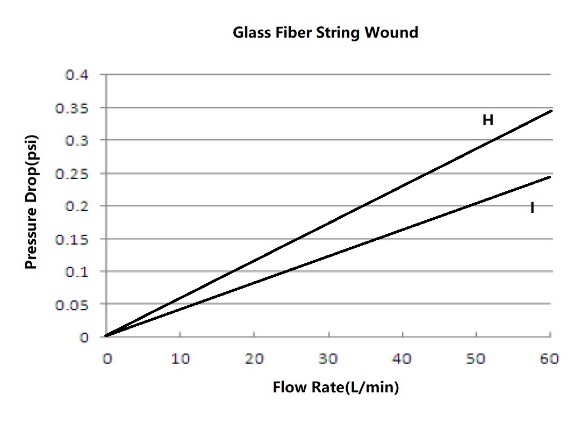

F-1.0μm

F2-1.2μm G-2.0μm H-5.0μm I-10.0μm J-20.0μm K-50.0μm L-100μm M-150μm |

D1-DOE

B1-222/Flat B3-222/Fin C1-226/Fin C3-226/Flat S-Self-seal Spring X-Extended Core |

P-PP

4S-304 SS 6S-316LSS |

S-Silicone

E-EPDM N-NBR V-Viton |

- ORIENTFILTR TECHNOLOGY CO.,LTD

- No. 688, Xingfu Road, Chongchuan District, Nantong, Jiangsu, China. 226007

- Email: info@orientfiltr.com

- Phone: 800-293-3858