How to choose suitable sanitary housing

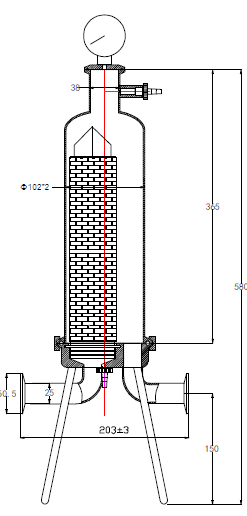

The stainless steel microporous filter is composed of a folded microporous membrane filter cartridge and a stainless steel outer cylinder. It is equipped with a single or multi-core filter cartridge. The filter cylinder is connected by a quick-release clamp or quick-opening ring bolt. convenient. The inner surface of the filter is mirror-polished, there is no sanitary dead corner, and it meets the requirements of “GMP” specifications.

Performance characteristics of sanitary filter (microporous membrane filter)

- Small size, light weight, easy to use, large filtering area, low clogging rate, fast filtering speed, no pollution, good thermal and chemical stability.

- It can filter out most of the particles, so it is widely used in fine filtration and sterilization process.

- Sanitary mirror polished inside and outside, in line with sanitary standards.

- The socket of the filter cartridge is processed by precision boring, and the installation of the filter cartridge is accurate and quick.

- It is widely used in pre-filtration and terminal precision sterilization filtration in food, beverage, medicine, biology, microelectronics, cosmetics, water treatment, wine making, electronics, petrochemical and other industries.

Main technical indicators of sanitary filter (microporous membrane filter)

- The filter housing can be installed with filter cartridges ranging from 1 round to 100 rounds, which can be tailored according to flow requirements.

- The length of the pleated filter cartridge is 10″, 20″, 30″, 40″

- The filter cartridge is made of Polypropylene, Polytetrafluoroethylene, and Polyethersulfone.

- The micron rate are 0.1, 0.22, 0.45, 1, 3, 5, 10, 20, 30, 50, 60μm, etc., which are divided into hydrophobic (applicable to gas) and hydrophilic (applicable to liquid) filter cartridges, according to needs Optional.

- Various interface respirators can be customized.

Main technical parameters of sanitary filter (microporous membrane filter)

Design pressure: 0.6/1.0/1.6Mpa

Design temperature: 5℃~100℃ (notice if over 60℃)

Sealing type: O-ring or flat washer

Interface form: GB, HG, DIN, ANSI, JIS standard flange, tooth mouth, clamp, etc.

Applicable filter cartridge: flat mouth, thread, 222 and 226 bayonet filter cartridges, etc.

Replacement pressure difference: 0.05MPA

Material quality: SS304, 316L, carbon steel rubber lining

Precautions for sanitary filters:

- The filter follows the combination configuration of coarse filtration first and fine filtration, and the order cannot be reversed;

- The actual flow, pressure and temperature of the compressed air passing through the filter housing cannot exceed the value specified on the nameplate

- When installing, distinguish the inlet and outlet positions of the filter, and do not install it backwards;

- For filters without automatic drainage, the ball valve should be opened regularly to remove the water accumulated in the filter, no less than 2 times a day.

- The inlet temperature of the filter housing can’t exceed 66℃

- ORIENTFILTR TECHNOLOGY CO.,LTD

- No. 688, Xingfu Road, Chongchuan District, Nantong, Jiangsu, China. 226007

- Email: info@orientfiltr.com

- Phone: 800-293-3858