How to choose suitable filter in brewery process

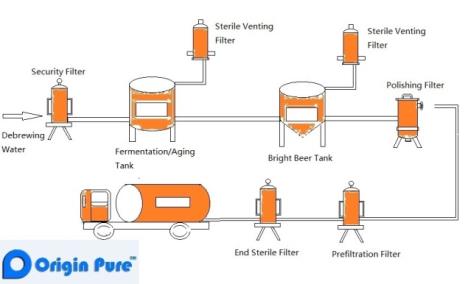

As we know, MF, UF, NF RO etc filtration technology had been widely used in beer production. But how to use correct and suitable filter or technology is a big question in this field. For one thing, the filtration material is special, for another thing, micron rate and filtration performance are different for plant. The process include water, beer etc liquid, but also air, CO2, N2, steam etc gas.

Right now let clarify and explain different kinds of filtration to guide user to choose suitable filter for brewery.

1.Micro Filtration Membrane:

The media would be polymer material to remove bacteria, yeast etc microganics, reuuber matrix, suspend dirty etc small particles.

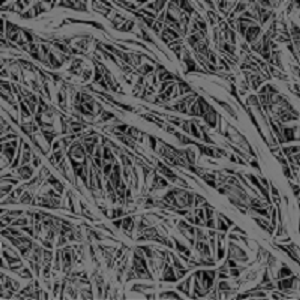

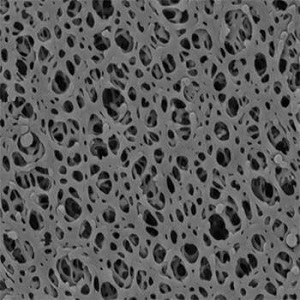

In general, MF membrane has faveolate material and intertexture material as below:

2.Micro Filtration Filter:

The filter have security filtration to remove big particles, suspended dirty; polishing filtration to catch the small particles and reuuber matrix etc; sterile filtration to block bateric, yeast etc.

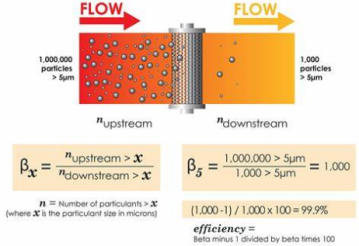

3. Filtration Effeciency Rate:

Absolute Filtration: Beta 5000/99.98% effieciency rate, if filter met integrity test requirement, in general, PES, PTFE, PVDF, NY own this feature; Norminal Filtration: 50~98% effeciency rate, depth filter is included.

4. Filter Recommedation:

| Target | Particle Size | Media | Micro Rate | Recommend |

| Big Particles | >40μm | PP | Norminal 5μm | PPL Series |

| Suspend dirty | N/A | PP | Absolute 0.5~3μm | PPA Series |

| Bacteria | >0.45μm | PES/PTFE | Absolute 0.1 ~.045μm | S Series OR OPT Series |

| Endortoxin | >0.05μm | NY | Charged Ny 0.22um | NA |

- ORIENTFILTR TECHNOLOGY CO.,LTD

- No. 688, Xingfu Road, Chongchuan District, Nantong, Jiangsu, China. 226007

- Email: info@orientfiltr.com

- Phone: 800-293-3858